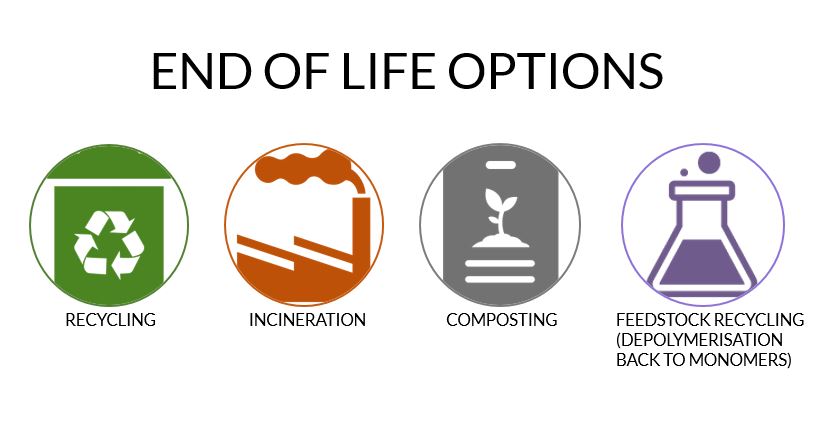

At the end of the materials’/products’ life cycle it is important to understand what options one has and how they impact the environment. There are several options for end of life for ArcBiox™ materials. They include all the same as for oil based plastics added by a few more environmentally friendly solutions. There is still much to do in terms of infrastructure to support all these end of life solutions and we are actively looking into this progress with our suppliers.

1. Mechanical recycling

Mechanical recycling is an important part of the circular economy. ABM has made an extensive test series with their materials, which showed excellent properties after pre-consumer mechanical recycling.

One of the topics that has been discussed is how to separate different waste streams and what is the bioplastics effect in this process. NIR (Near-Infrared) is one of the processes where PLA can be detected in the waste stream.

2. Incineration (with energy recovery)

This is a global option for end-of-life. In many geographic areas composting is not yet supported by infrastructure and hence incineration is a viable option. The analysis made by one of our PLA suppliers (NatureWorks) showed no volatile and low residue when burning their polymer.

3. Composting (organic recycling)

Most ArcBiox™ composites are compostable in an industrial compost. In this environment the moisture and heat in the compost pile split the polymer chains apart, creating smaller polymers, and finally, lactic acid. As the polymer degrades the ArcBiox™ fibers are exposed to the environment and they brake down to the minerals. The microorganisms in the compost consume the smaller polymer fragments and lactic acid as nutrients.

Arctic Biomaterials Oy has certified one of the degradable glass fiber composites with the Seedling mark Din Certco EN13432 up to a thickness of 2 mm as a proof of concept. In addition, home compostable materials are under development.

4. Chemical recycling

The chemical recycling process also known as back biting is not very widely used today. One of our suppliers NatureWorks has recycled more than 17 million pounds of their Ingeo biopolymer in the US. In this process, called the hydrolysis process, the biopolymer is broken down into lactic acid. Following the hydrolysis process the lactic acid is then converted back to biopolymer resin.