The two key indicators in a products’ environmental footprint are greenhouse gases and non-renewable energy use. In some cases compared to traditional technical plastics the amount of greenhouse gases and use of non-renewable energy (per kg of polymer produced) can be reduced as much as 60-80% by using ABM compounds. For the final calculation/comparison, the Life Cycle Analysis (LCA) tool should be used.

Arctic Biomaterials approach to LCA

Incorporating a life-cycle assessment (LCA) into research and development is a valuable method at ABM, as our customers have a strong need to have proof about the sustainability value of the material they purchase and use as sustainable alternative. In the past, ABM has relied on declarations by its raw material suppliers on environmental declarations. These peer-reviewed environmental claims are only sufficient to a certain point. ABM purchases bio-based polymers from renewable sources and increases their environmental impact in its own manufacturing process, which produces bio-based plastics composite by adding bio-glass fibers based on ABM’s own technology.

Through the manufacturing process, ABM increases the environmental impact of a product by using energy and using global raw material supply chains. In addition to the choice of raw material, these effects have to be computationally added to the carbon footprint estimate to avoid possible unintentional green washing. The LCAs conducted by ABM is based on Environmental Footprint Database 2.0 and by using accredited GaBi datasets and by following principles and approaches outlined in ISO 14040 and ISO 14044. Different what if-material selection scenarios revealed that the manufacturing location and transportation distances effect to the total composite GWP is still being left behind by the material selection impact. If carbon uptake is credited, the GWP of products was significantly lower compared to fossil based polymers during the use phase.

Embodied energy from fossil sources during polymer production, processing energy and end-of-life emissions during incineration has the most significant impact Plastic product environmental impact formation during value chain. Use of carbon neutral material and biomass instead of non-renewable and fossil materials reduces fossil CO2 emissions and mitigates global warming. By using bio-based polymers the decoupling from fossil energy during material production is enabled.

After conducting what if scenario –type LCA for selected ABM-composite materials the performed life cycle assessment supports environmental claim that ABM produces environmentally friendly plastic alternatives. The future End-of-Life options and their challenges are acknowledged. Composting can be seen as an attractive alternative when cost of the waste management is linked to producer responsibility, or recycling is difficult through plastic product complexity.

Estimated 9/10 of plastic packaging is still ending up to incineration instead of recycling in Finland. How about non-packaging items?

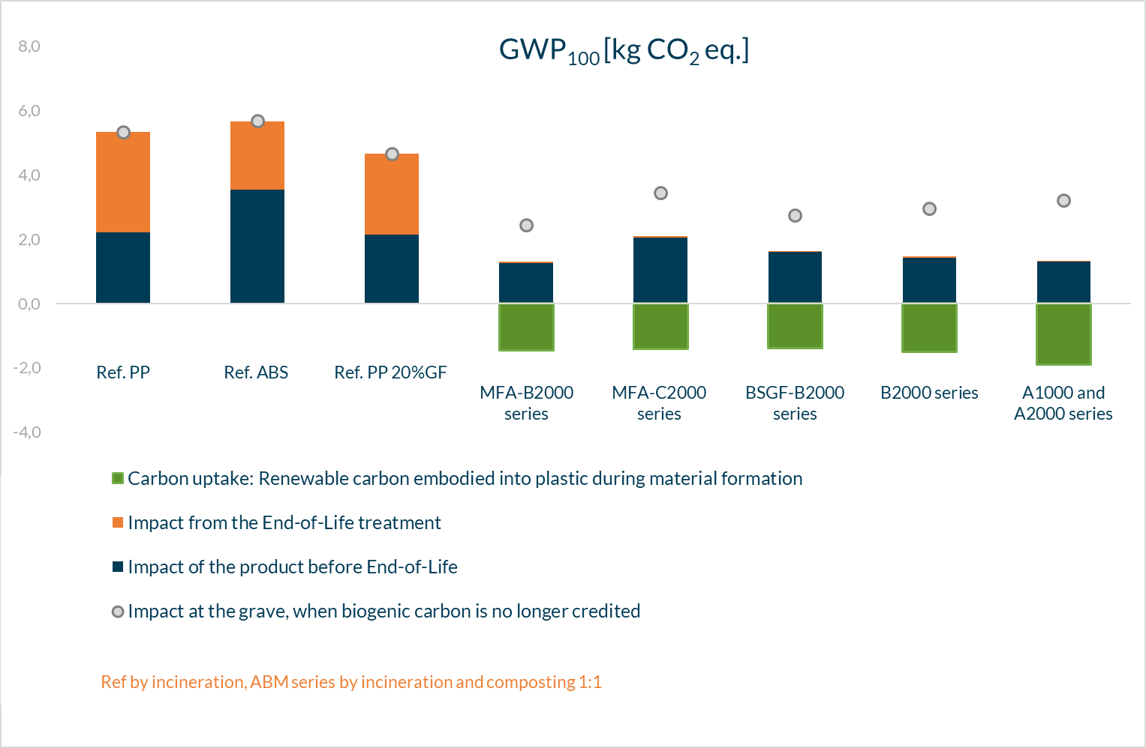

Figure below shows impact the difference between the fossil non-renewable carbon that is released from geosphere to atmosphere during end of life (orange) vs the renewable carbon embodied into product from atmosphere (green). ABM product series average impact is evaluated with end-of-life by incineration and composting compared to fossil alternatives EoL by incineration.

Disclaimer:Results from the calculations above must undergo independent critical review if they are to be used for comparative assertions. This information and all technical and other advice are based on Arctic Biomaterials Oy present knowledge and experience. ABM assumes no liability for such information or advice, including the extent to which such information or advice may relate to third party intellectual property rights. ABM reserves the right to make any changes to information or advice at any time, without prior or subsequent notice.

When choosing between different products or suppliers, the comparison between individual LCAs has to be conducted with extreme care. To conform to ISO standards, results from the calculations must undergo independent critical review if they are to be used for comparative assertions to be disclosed to the public.

The system boundaries used in assessment and product category rules (PCR) must be acknowledged. Different application areas, whether geographical, sectorial, or related to specific impact categories, may indeed require different kinds of data, specific definitions of functional units to make comparisons fair, and specific impact assessment methods.

Sustainable product design and system thinking is needed as we are living in a complex world and products are formed from multiple locations with variable parallel processes.

Contact us for more information