ABM Composite R&D has enabled +100 medical devices and raw material compositions in almost 100 R&D projects to our customers. We have a strong expertise in bioresorbable medical device development. Our R&D projects are provided with documentation in accordance with ISO 13485.

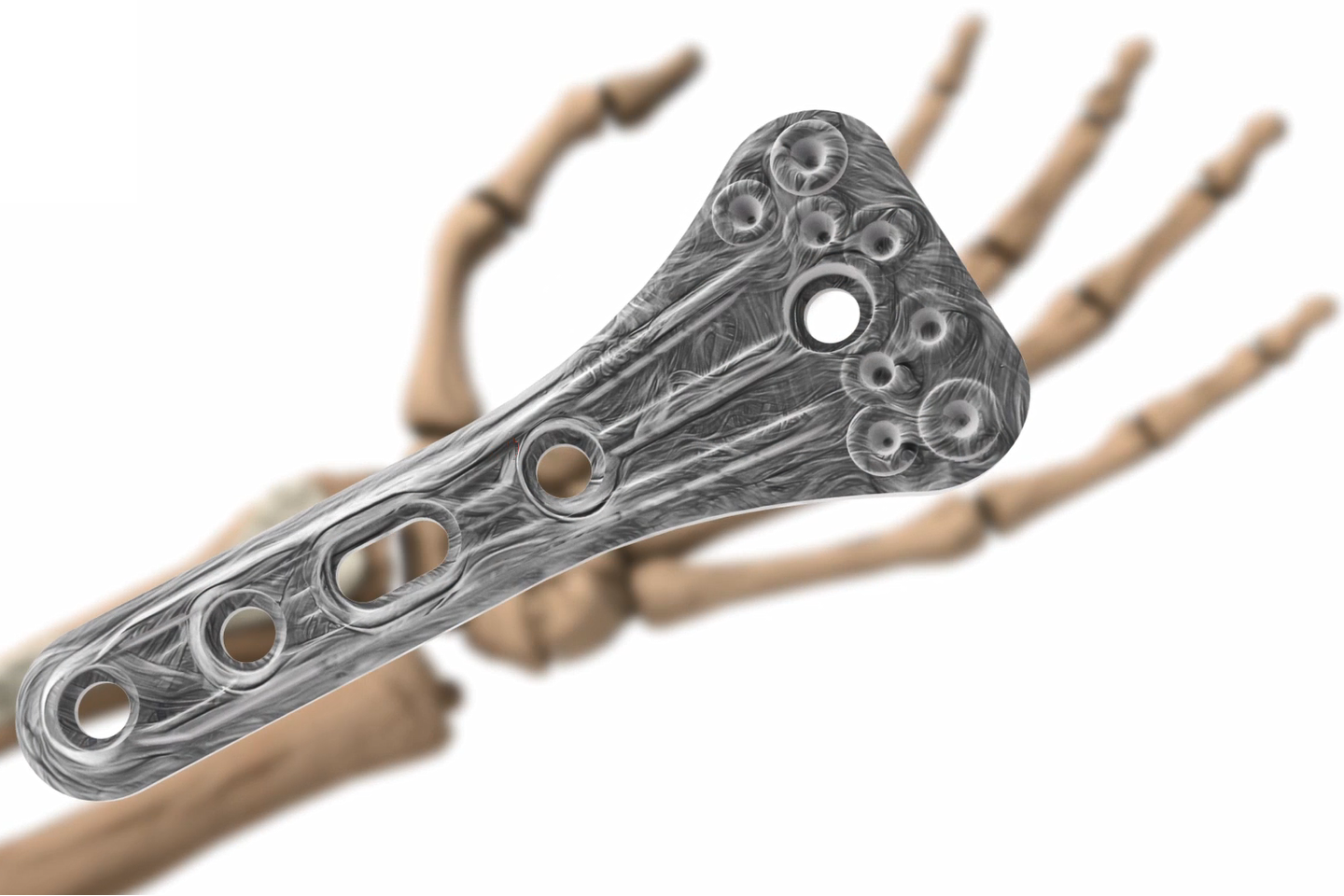

Implant design development

ABM Composite can support your prototype design of “the implant of dreams” to match the requirements and material characteristics.

- Designing (3D CAD + FEM)

- Medical devices e.g. suture anchors, screws, interference screws, fixation plates, nails

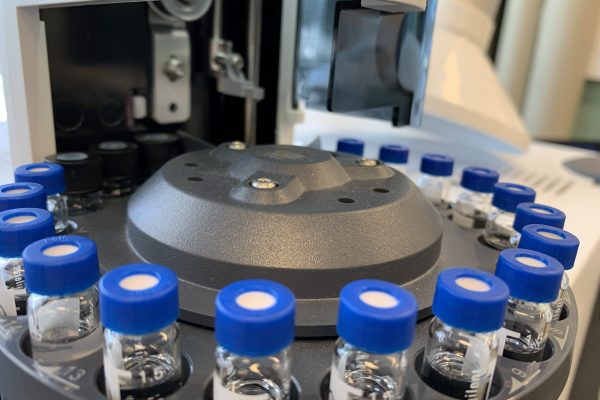

Pilot manufacturing

Prototypes are valuable, and we have multiple options to provide them. We can conduct a pilot for your device or implant to get the proper characteristics and materials for your design.

- Prototyping

- 3D printing and injection molding

Testing and feasibility

ABM Composite has the majority of the testing capabilities required in-house.