All plastics are affected by sunlight, heat and moisture. Even if the final plastic product is designed for indoor use, it may be subjected to very harsh conditions during transportation and storage. For example, the internal temperature of a car can reach more than 60 Celsius in the summer. Metallic sea containers may be subjected to elevated temperatures, large temperature fluctuations and container rain (condensated water inside the container).

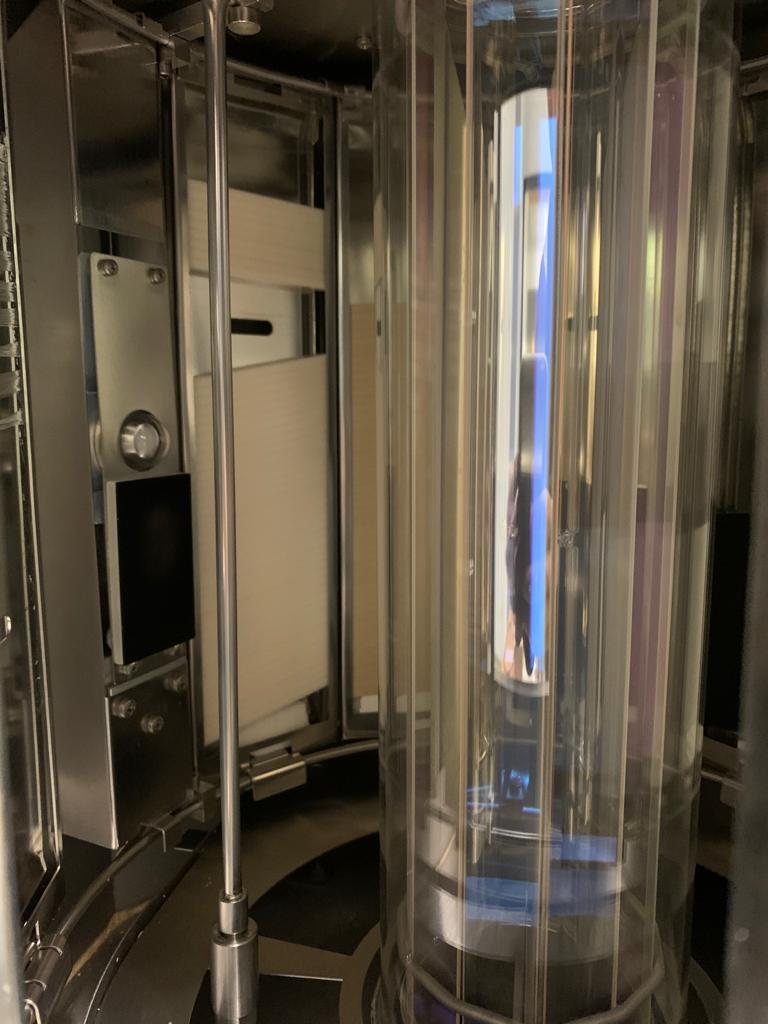

Solar cabinets provide a way to test the long-term properties of plastic materials or products in an accelerated, yet standardized manner. The samples are subjected to specified cycles of UV light (with similar radiation spectrum to natural sunlight), humidity, elevated temperatures and periodical water sprays. After exposure, the materials are evaluated visually and mechanically. The test procedures can be selected to simulate outdoor conditions at a certain reference area or extreme indoor conditions similar to a black car dashboard in the summer.

Arctic Biomaterials tests all their commercial grades in an accelerated outdoor weathering test

Accelerated weathering tests enable studying the long-term properties of novel, cutting-edge materials such as bio-based and biodegradable ArcBiox materials. Arctic Biomaterials continuously screens materials in their solar cabinet according to EN ISO 4892 standards.

Ari Rosling, the R&D director: “Biodegradable plastics and composites are often marketed for single-use applications, but our materials suit re-usable applications very well. We have been able to prove this to our customers with the accelerated weathering tests. For instance, one of our bio-based and biodegradable development grades has shown similar mechanical performance with less yellowing compared to non-degradable reference ABS. The harsh test was performed up to 1000 hours in the solar cabinet, which corresponds to at least 1 year of outdoor solar radiation dosage in a benchmark climate of Southern Europe at 25-30 Celsius.”

Accelerated vs. natural weathering

Accelerated weathering tests provide an excellent tool for comparing the behavior of different materials in standardized weathering conditions. Still, it needs to be noted that the acceleration factors are material and environment specific. For example, the color of the material can affect its temperature during radiation dosing, or certain additives may cause chemical reactions leading to faster aging.

Theoretical acceleration factors are often below 10. However, a study [1] comparing accelerated weathering in a solar cabinet to natural outdoor aging in China using two polymer types (PE and PC) found that the real acceleration factors ranged from 36 to 67. This kind of very high acceleration factors are possible, making natural weathering tests equally important for material development. For this reason, Arctic Biomaterials is also continuously performing laboratory tests after weathering in Finnish outdoor conditions.

References

[1] Yang, Li, Zhang (2006) A new approach of studying correlation between outdoor exposure and indoor accelerated corrosion test for high polymer materials, Journal of Wuhan university of technology vol.21 no.4. https://doi.org/10.1007/BF02841218