Bio-based materials can be used to help de-couple the society from fossil fuels. In this blog post, we present the life cycle assessment (LCA) of ArcBiox™ compounds and composites. Furthermore, we discuss the views of consumers and brand owners on bio-based materials.

ArcBiox™ – science-backed, sustainable material solutions

Bio-based materials are made from biomass (e.g. plants or organic waste) and thus bind renewable carbon from the atmosphere. This renewable carbon is released back into the atmosphere when the materials are incinerated or composted, but the net amount of CO2 is not increased. On the contrary, fossil-oil based materials effectively transfer carbon from inside the earth’s crust into the atmosphere. This is because they are made from non-renewable fossil carbon; oil is pumped from the earth’s crust and used to produce fuels and plastics, which are later incinerated and release their carbon into the atmosphere. This increases the net amount of CO2 in the atmosphere and thus accelerates climate change.

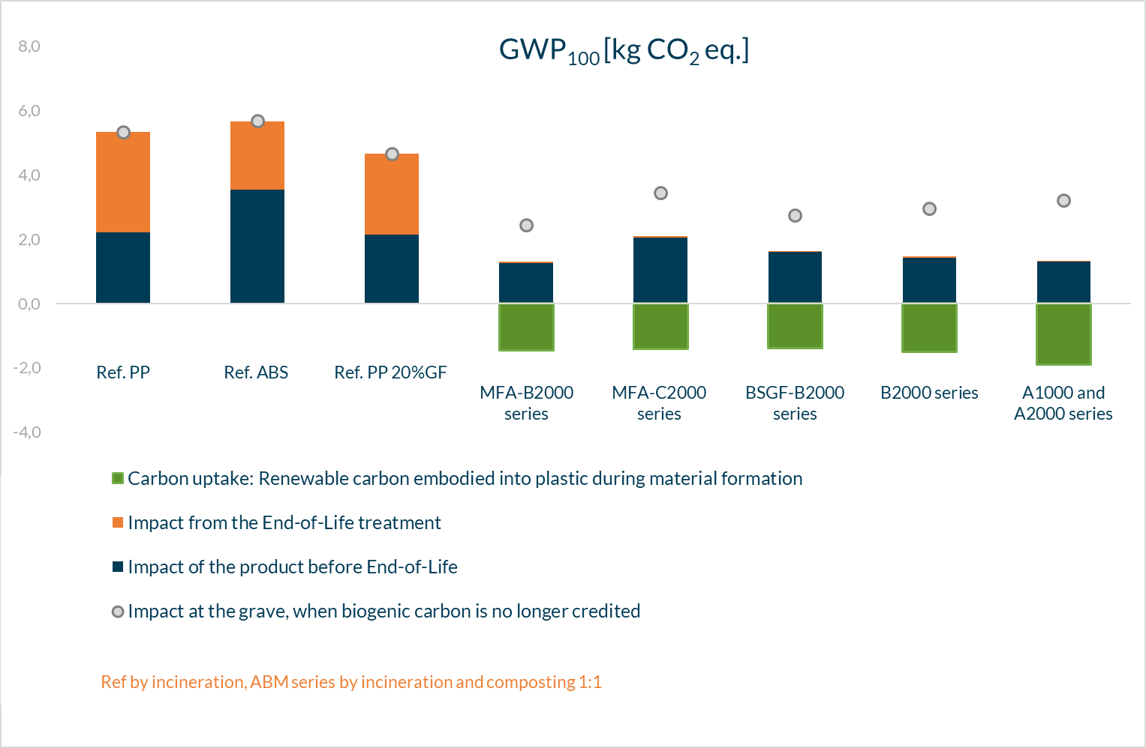

Arctic Biomaterials performed various life-cycle assessment (LCA) scenarios* to study the environmental footprint of bio-based ArcBiox materials. These scenarios revealed that fossil-oil based materials have two main constituents for their environmental footprint: the materials themselves due to their non-renewable carbon and the energy that is used to produce the materials. In contrast, the environmental footprint of bio-based ArcBiox materials mainly consists of the energy used in the manufacturing process. This is because the renewable carbon in ArcBiox materials returns to the atmosphere (where it originates from) and can be credited in the analysis. Other factors like transportation footprint of the raw materials were noticed to be insignificant compared to the material origin (bio- or fossil-based).

Figure 1 presents the average environmental impact of ArcBiox grades compared to virgin fossil oil-based references. The chart shows the global warming potential (GWP), which indicates that 1 kg of any of the ArcBiox grades produces significantly less CO2 emissions compared to fossil oil-based reference materials such as polypropylene (PP) or acrylonitrile butadiene styrene (ABS).

The LCA showed that Arctic Biomaterials produces sustainable material solutions. In addition, the possibility to compost ArcBiox materials provides opportunities to replace materials that are otherwise difficult to recycle. Thus, organic recycling via composting may help companies to fulfill their obligations related to producer responsibility.

Figure 1. The global warming potential of fossil-oil based reference materials (PP, ABS, PP+GF20) and ArcBiox products, illustrated as the amount of CO2 equivalent that is produced by 1 kg of material. GWP100 is a global metric that addresses the average global warming potential of a material over the next 100 years.

*The LCAs conducted by ABM are based on Environmental Footprint Database 2.0 and utilize accredited GaBi datasets and scientific data. The assessments have followed the principles and approaches outlined in ISO 14040 and ISO 14044.

Switching to bio-based materials

There is a heavy connection between plastics production and petrochemistry, as 99% of the plastics produced in 2020 originated from fossil oil-based feedstocks [1]. Consumers and brand owners can contribute to breaking this connection e.g. by choosing bio-based products, where the raw materials originate from biomass such as plants or organic waste.

According to a recent survey [2], the main drivers for growing bio-based product demand are:

(i) Customer preference for products with low environmental impact (73% of interviewed brand owners)

(ii) Improved customer awareness (71% of interviewed brand owners).

At the same time, consumers (81% in the Netherlands, 93% in Ireland) indicated that they prefer buying bio-based products rather than fossil-based products.

The results indicate that a transition away from fossil-based materials is beginning and consumer behavior plays a significant role in this evolution.

References:

[1] Nova Institute report “Bio-based Building Blocks and Polymers – Global Capacities, Production and Trends 2020–2025”. Available: https://renewable-carbon.eu/publications/[2] European survey by BIOSWITCH on needs, risks and motivations for brand owners and consumer to switch to bio-based solutions (December 2020). Available: https://clicinnovation.fi/join-the-bioswitch-webinars-on-20-january-and-on-27-january/